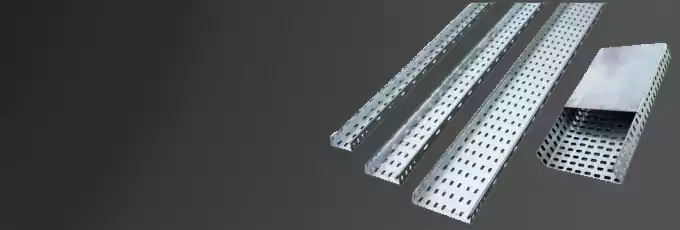

We are Manufacturer, Supplier, Exporter of Raceway Cable Trays, Cable Tray Ducts, Trunking Cable Trays, Pre-Galvanised Raceway Cable Trays, GI Raceway Cable Trays, Hot Dip Raceway Type Cable Trays, Galvanized Iron Cable Trunking, and Our Setup Situated in Pune, Maharashtra, India.

|

Standard Length |

2500 mm |

|

Thickness |

1.2 mm to 2 mm |

|

Height |

15 mm, 25 mm. |

|

Width |

50 mm, 75 mm, 100 mm, 150 mm, 200 mm, 250 mm, 300 mm, 350 mm, 400 mm |

|

Finish |

Pre-GAlvanised and G.I. Hot Dip. |

U-Protec Cable Trays Pvt. Ltd. specializes in manufacturing, exporting and supplying various Cable Trays and Accessories not only in India but across the globe.Backed by a substantial industry experience, we blend modern manufacturing methods with innovative techniques to deliver high grade, reliable cable support systems. With a focus on sustainability, all our products are crafted from high quality, recyclable materials and we actively work to reduce waste.

Raceway Cable Trays play a vital role in foundry environments, offering a reliable solution for cable management and organization in demanding industrial conditions. These cable trays provide a structured pathway for electrical wiring, helping to minimize clutter and enhance operational safety.Raceway trays are designed to protect and support cables against extreme heat, mechanical stress and dust accumulation common challenges found in foundry operations.The integration of wire trays within the system ensures durability, prevents cable tangling and allows easier access for maintenance. Proper cable management in foundries is essential for uninterrupted workflow and electrical trays support power distribution systems efficiently while maintaining an organized setup.

With their robust design,raceway trays are essential for ensuring the longevity of electrical infrastructure by preventing cable damage and enhancing stability. Effective cable management allows foundry operators to optimize space,simplify troubleshooting and reduce the risks associated with cable exposure. The use of high quality electrical trays helps prevent system failures by securely housing wiring and reducing vulnerability to external elements.Raceway trays enhance electrical safety and functionality in industrial units, guaranteeing reliable performance of foundry machinery.

The integration of cable trays into foundry setups serves to improve operational efficiency while maintaining safety standards. Wire trays enhance accessibility, making inspections and modifications more convenient. As foundries require structured electrical solutions, raceway trays provide an organized approach that keeps wiring systems secure and manageable.

1. Steel Raceway Cable Trays: These are strong and corrosion resistant trays ideal for heavy duty industrial use.

2. Aluminum Raceway Cable Trays: These type portray lightweight and durable trays suitable for high temperature environments.

3. Ladder Raceway Cable Trays: They have open structure trays designed for maximum ventilation and cable support.

4. Solid Bottom Raceway Cable Trays: Such types are fully enclosed trays that offer maximum protection against dust and debris.

5. Fiberglass Raceway Cable Trays: They represent non-conductive and corrosion resistant trays ideal for sensitive electrical applications.

- Foundries

- Production Plants

- Oil and Gas Industry

- Power Supply Plants

- Infrastructure

- Chemical Plants

- Food and Beverage Industries

1. Long Lasting Products: Our steel raceway cable trays and aluminum raceway cable trays are built to withstand extreme conditions, ensuring reliability.

2. Enhanced Safety and Protection: Our solid bottom raceway cable trays safeguard cables from dust, debris and environmental hazards, reducing maintenance efforts.

3. Optimized Heat Dissipation: Our ventilated raceway cable trays allow proper airflow to prevent cable overheating, improving system performance.

4. Lightweight Options: Our fiberglass raceway cable trays provide a non-conductive and rust proof solution for sensitive environments.

5. Superior Cable Management Solutions: Our raceway trays ensure organized and efficient cable management, minimizing clutter and maximizing safety.

6. Expert Engineering: With deep expertise, our team delivers most modern cable trays tailored to the latest industry standards and demands.

U-Protec Cable Trays Pvt. Ltd. is a prime manufacturer, exporter and supplier of best quality of a wide range of cable trays, ducts and cable accessories engineered for construction, infrastructure, energy and industrial use. Our modern facilities and technical expertise enable us to offer specialized solutions for every application. From cable trays to varied parts and components, our products are delivered efficiently and economically.

Cable tray ducts are essential components in the sector of electrical infrastructure, particularly within foundries where efficient cable management is crucial. These systems are primarily manufactured from materials such as steel, aluminum and PVC, each chosen for their unique properties that cater to specific industrial needs. For instance, PVC cable tray ducts for electrical wiring are favored for their lightweight nature and resistance to corrosion, making them ideal for environments where moisture is a concern. On the other hand, perforated cable tray ducts for industrial use provide excellent ventilation and heat dissipation which is vital in high temperature settings like foundries. The durability of cable ducts is supreme,specially in heavy duty applications where they must withstand significant wear and tear. Manufacturers often focus on creating fire resistant cable tray ducts to ensure safety in power distribution systems, particularly in commercial buildings where compliance with safety regulations is mandatory.

The design of cable tray duct systems is also critical, as they must accommodate various cable sizes and types while ensuring ease of installation and maintenance. Effective cable management is achieved through the strategic layout of wire ducts which help organize and protect electrical wiring from damage. The selection of materials and design features plays a significant role in the performance and longevity of these cable management solutions, ensuring that they meet the rigorous demands of modern electrical systems.

1. Channel Cable Tray: It displays a cable tray with a channel like design, allowing for easy cable installation and management.

2. Trough Cable Tray: This type portrays a cable tray with a trough like design, providing a high level of cable protection and support.

3. PVC Cable Tray: Such category exhibits a cable tray made from PVC, offering a lightweight and corrosion resistant solution.

4. Aluminum Cable Tray: This model features an aluminum cable tray, offering a rustproof and easy to handle structure.

- Aerospace

- Utilities and Infrastructure

- Pharmaceuticals

- Food and Beverage

- Mining and Metals

- Transportation and Logistics

- Automotive Industry

1. Best Quality Materials: We utilize premium materials such as steel, aluminum and PVC, guaranteeing durability and longevity in our cable tray products.

2. Innovative Manufacturing Techniques: We employ latest and advanced manufacturing processes that enhance the quality and precision of our cable trays, resulting in superior products.

3. Extensive Product Range: Our extensive variety of cable trays accommodates various applications, providing clients with dynamic solutions for their cable management needs.

4. Timely Delivery: We prioritize prompt delivery schedules, ensuring that our clients receive their products delivered in a timely manner to meet the deadlines.

5. Competitive Pricing: We offer best quality cable tray ducts at competitive prices, ensuring value without compromising on quality.

6. Transparent Practices: We focus on transparent practices and approach in our method of business so that our customers are made aware of each and every thing related to our transactions.

At U-Protec Cable Trays Pvt. Ltd., we are a leading manufacturer and supplier of an expanding range of cable trays and related products. Our in-house manufactured offerings include Ladder Cable Trays, Metal Cable Trays, Cable Tray Accessories, Hot Dip Raceway Cable Trays,Galvanized Iron Cable Trunking Trays and many more associated products.Fabricated from various materials,our cable trays are available in multiple types to suit diverse requirements. These products are ideal for integration into electrical systems, guaranteeing reliable cable management.

Trunking Cable trays provide essential cable management solutions for organized and protected wiring systems. A trunking tray, as it is often called, is designed to enclose and route cables securely, offering an alternative to open cable trays.Trunking provides a channel to protect cable that might get damaged. The materials used in the manufacture of trunking cable trays are crucial to their performance and longevity. Metal cable trays, specifically steel and aluminum, are commonly employed due to their strength, durability and ability to provide electromagnetic shielding. Steel trunking cable trays, often finished with a powder coated trunking cable trays surface to improve corrosion resistance, are widely used in industrial environments requiring robust protection. Aluminum trunking cable trays are lighter in weight and offer excellent durability against rust and wear, making them suitable for outdoor applications.

In commercial and industrial environments, cable management and trunking systems are essential for arranging and securing electrical wiring. These trays with cover further enhance protection by fully enclosing the cables,preventing dust and accidental contact. When selecting trunking,factors such as load capacity,environmental conditions and accessibility for maintenance must be considered. Reliable trunking cable tray suppliers offer tailored solutions in different sizes and designs to match a variety of installation needs. For demanding environments, durable trays for wiring provide a reliable solution to protect and manage critical cabling infrastructure. Trunking cable trays for industrial use often require specific certifications and standards compliance to ensure safety and performance.

1. Solid Bottom Trunking: These types provide maximum cable protection with a completely enclosed design.

2. Ventilated Trunking: Such category offers airflow to prevent cable overheating while maintaining enclosed protection.

3. Wire Mesh Trunking: This kind of trays use a wire mesh structure for lightweight support and ventilation.

4. Fiberglass Trunking: Fibreglass Trunking offers corrosion resistance and is suitable for harsh environments.

- Commercial Buildings

- Industrial Facilities

- Healthcare Facilities

- Transportation Infrastructure

- Educational Institutions

- Manufacturing Plants

1. Enhanced Cable Protection: Our trunking cable trays provide superior cable protection, safeguarding the infrastructure of our customers from physical damage, dust and environmental factors, guaranteeing reliable performance.

2. Organized Cable System: Designed for high performing cable organization, our systems simplify routing and maintenance, reducing clutter and enhancing overall system accessibility.

3. Adaptable Solutions: We offer a wide variety of designs for a variety of products manufactured at our unit, allowing for easy customization to accommodate infrastructure expansions.

4. Durable and Excellent Performance: Manufactured from best quality materials, our cable trays are built to withstand harsh environments, guaranteeing long term durability and minimizing replacement costs.

5. Easy Installation and Maintenance: Our user friendly layouts promote quick and easy installation, reducing labor costs and facilitating adjustments and upgradation.