We are Manufacturer, Supplier, Exporter of Cable Tray Accessories, Ladder type Cable Tray Accessories, Perforated Type Cable Tray Accessories and Our Setup Situated in Pune, Maharashtra, India.

Items | Thickness |

GI Z Channel 30*35*30 MM | 1.2 MM |

GI Supports C Channel | 1.2 MM |

GI Threaded Rod | 8 MM, 10 MM |

Anchor Bullet Fastener For Rod | 8 MM, 10 MM |

Support Patti | Standard |

Nut Bolt & Coupler Patti | Standard |

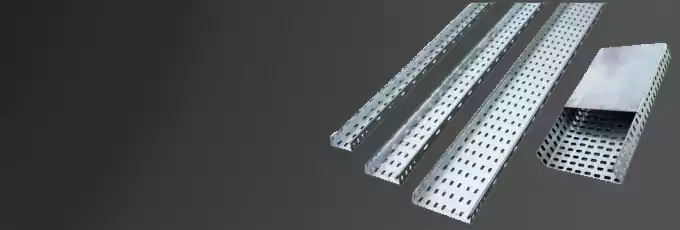

U-Protec Earthing Pvt Ltd We are engaged in the manufacturing, supplying and exporting of a wide range of products Perforated Cable Trays, Ladder Type Cable Trays, Cable Tray Covers, Raceway Cable Trays, Trunking Cable Trays and many more related products.These products are offered in various grades and specifications to meet diverse customer requirements. With the support of advanced machinery and modern facilities, we efficiently manufacture high quality cable management systems at scale. We are committed to timely delivery and demonstrate transparency in all our operations.

Cable tray accessories are essential components used in cable management systems to support, secure and organize electrical wiring. These accessories ensure the efficient routing of cables, preventing clutter and minimizing potential hazards associated with loose wiring. Raceway accessories are used to provide additional protection to cables, ensuring a safe and streamlined electrical infrastructure. These accessories are constructed from various materials based on their application and the environmental conditions they need to withstand. Steel is one of the most widely used materials, particularly for industrial cable tray accessories, due to its strength and durability. Galvanized steel is a popular option as it offers corrosion resistance, making it ideal for environments where harmful chemicals are present.Stainless steel is another material for cable tray accessories,known for its strong resistance to rust and temperature conditions. Aluminum is one of the commonly used material due to its lightweight nature and resistance to oxidation. It is utilized in situations where weight constraints are a factor. Manufacturers use both polymer based and fiberglass reinforced plastics in producing cable tray accessories.

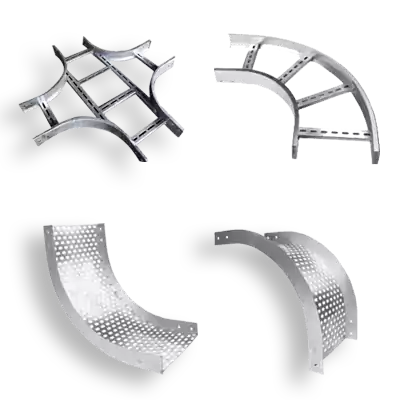

Cable Tray Bends: Cable tray bends allow for smooth directional changes in cable trays, whether horizontally or vertically.

Elbows: They allow the cable tray to make a 90 degree turn to go around existing structures.

Tees: These objects enable the branching of cable trays into three directions for complex cable distribution.

Couplers: They serve to attach two straight cable trays together securely, supporting length expansion in cable systems.

Reducers: These components help reduce the size of cable tray system, as per requirements.

Cable Tray Covers: These covers safeguard cables against environmental exposure and contribute to a safer cable management setup.

Support Brackets: These brackets ensure that cable trays remain secure and strong enough to carry heavy cables.

- Virtual Server Centers

- Operational Sites

- Engineering Projects

- Solar Power Energy

- Automotive Industry

- Wiring Management Solutions

Upgraded Wiring System: Our cable tray accessories guarantee organized wiring, reducing clutter and enhancing the functionality.

Long Lasting Quality: Our galvanized cable tray accessories are built to resist corrosion, ensuring they perform well and last for a long time.

Custom fit Solutions: Our tray fittings are designed for precise installation, providing uninterrupted connection in complex electrical systems.

Safety Compliance: The cable tray parts fabricated at our unit help maintain secure electrical wiring systems, minimizing fire hazards and ensuring regulatory compliance.

Optimized Cable Protection: The covers and fittings produced by us, shield cables from physical damage, extending the life of electrical wiring systems of our valued customers.

Low Budget: By organizing cables efficiently, our accessories are low budget and they facilitate easy inspection and repair, reducing downtime.

Innovative Design: We prioritize advanced design and development to deliver high performance cable tray fittings built for industrial reliability.